Features

The beveller needs no track to move along steel plate to produce accurate high-quality double-side bevels without thermal distortion or creation of heat affected zone on plate thickness range 8 - 60mm.

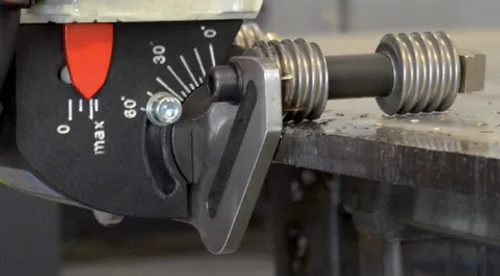

The ABM-30 features an infinitely adjustable bevel angle between -70° and +70° and is capable of producing bevels up to 30mm wide.

It also allows for facing in both directions with the milling head depth of 1mm.

- Needs no track to travel in both directions with feed speed up to 2m/min.

- 4 Wheels feed drive eliminates hard physical work of the operator.

- Produces double-side bevels without having to flip the plate enhancing safety and reducing material handling time and expense.

- Edge to edge working range.

- Semi-automatic feed stop at end of the metal sheet.

- Variable spindle speed.

- Bevel width up to 30mm (1-3/16").

- Variable angle -70° to +70°.

- Max. plate thickness up to 60mm.

- Innovative, robust chip protection solution.

Specifications

- Voltage: 1~ 200-240 V, 50/60 Hz

- Power: 2200W

- Spindle Rotational Speed (Without Load): 1800 - 5850rpm

- Feed Speed: 0 - 2m/min

- Bevel Angle (ß, Fig. 1): From -70° to 70°

- Maximum Bevel Width (b, Fig. 1): 30mm

- Sheet Thickness: 8 - 60mm

- Required Ambient Temperature: 5 - 40°C

- Weight: 43kg

Description

Bevelling Measurements:

Machine Dimensions:

Features:

Control Panel

- Feed direction indication

- Material detection

- Bar graph for motor load illustration

- Visual warning signals

Precise Bevel Angle Setting

Convenient Adjustment To Plate Thickness

Operating Methods

- Top bevelling

- Bottom bevelling

- Facing-off

Optional Accessory:

Transportation and storage trolley